When I first heard and saw Titus I thought to myself what awesome grinders,. So I contacted Titus to enquire about a new grinder and yet I had no idea what they were really all about. Almost a year later, I am still without my new grinder, but I have a much better sense of the work involved. However I am closer and closer to finalizing my selection of customized parts and that’s no fault of Titus owner Frank Durra.

If it looks easy, think twice, because this quality is hard to find, and it takes time and patience if you are after perfection – I am. All Titus parts are carefully examined, machined to precision and Frank is proud about that, and rightly so. It would be impossible to have the output of Titus and maintain the quality if he wasn’t a control freak.

Over the past year I felt as if I lived in the Titus backyard, connected to what’s up we talk everyday about grinder details, finishes, challenges, and the struggle of being a small business and dealing with high-end clients. Frank would say his clients are sometimes a pain in the ass and that’s me. I take my time and try to create a creative process that pushes details to the limit.

These grinders I would say are hausgemacht, (home-made) yet don’t take that the wrong way. Frank lives in his custom workshop, and spends more time there than he does at home. Almost all the time there or on the road getting a part finished, or picking up supplies.

He prides himself on minimum gap dimensions between parts, studies the details over and over again to get them right. Very critical of his own work, is the only way Frank works. Frank doesn’t like selling anything junky and is careful about what he calls “cheapy-Cheap” as he tells me, he will need to plate my lever, a custom part made from stainless steel. I was the one who asked that the knob at the front be changed to a lever. Also I asked Frank to eliminate the small coffee drawer for grounds at the bottom of his grinder base.

Now when it comes to building a grinder the road is long and winding. Titus grinders is owned by a savvy native German who spends most of his time trying to stay up late at night and work all day long. He is used to it, a former truck driver, he is has stamina. When Frank doesn’t sleep he’s in full throttle at his workshop, and almost anytime of the day or night you can find Frank on-line.

Frank spends more time motivating his clients in the right direction. I know from my experience that building a grinder takes lots of time and of course money. His grinders can range depending on the level of customization from €5,000-10,000+ and for a good reason. But many non-coffee drinkers would think anyone is crazy to pay so much for a grinder. But if you want the best looking grinder in the world, it’s a fair price.

So building a grinder looks like easy-peasy but just the opposite is true. I have spent countless hours, and he has spent more trying to pin down the innumerable hours that go into getting a grinder perfect. In the beginning I admit I was completely ignorant of how much effort it takes. Mostly because its hard to believe the intensity of how Frank works, and the multitude of components that go into a grinder.

From the outside looking in, the grinders look so perfect you take for granted the actual working hours it takes. I am fascinated by Frank’s persistence to try to make each grinder individual and he does an amazing job. The work he puts into defining the finishes and the countless hours he devotes to each grinder is incredible.

Frank drinks lots of coffee from his collection of machines, which looks like a high-end coffee bar, but he seems to lean towards one in particular. He would need to say which one. Coffee is the main theme and grinding starts with the burrs, and they are superb. The quality of his burrs are incredible and the coatings he uses are from the tooling industry – perfectly executed for maximum precision and durability.

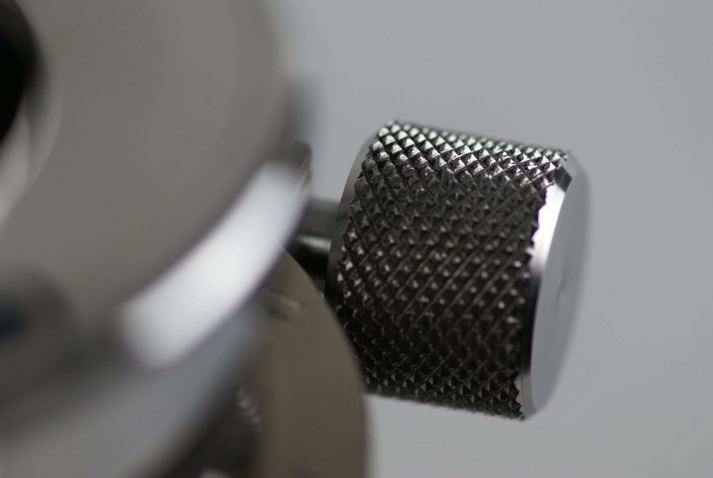

Then they are so many other parts, the nose, head, the body the middle plate, chutes, hoppers, chutes, dosing tools and so many other small parts that all need to be defined and refined. The one aspect of Frank’s work that defines Titus is the finishing of the body, electrical connections, and the shiny water reflections that are either DLC or PVD.

These processes are long and expensive given the amount of work to get any part to look right. Take PVD coated, physical vapour disposition: it takes two polishing, plating and coating to get any surface mirrored, and that’s just part of the story. Frank prides himself on what he does, and has a work classical and respectable work ethic. Without a question the grinders look superb and there is nothing on the market to compare – see for yourself and enjoy the magnificent work of a true artisan.

I want to say thank you Frank for his perseverance and dedication to a trade that is only made with pure passion, and all your time and patience – it is greatly appreciated.

See Here Titus Company Profile: fly_4-2015_titus-fh11

Categories: Facts

You must be logged in to post a comment.